100 SERIES OPERABLE WALL

Transform Your Space With Doormax

Doormax 100 series Acoustic Movable Partition System, a groundbreaking advancement in acoustic environments. By incorporating cutting-edge materials like steel sheets, sound-dampening mats, and acoustic panels, it achieves exceptional sound transmission levels (STC) ranging from 45db to 56db. The sturdy base board offers flexibility with options such as 15mm/18mm plywood, MDF, HDF, or HPL, laying the groundwork for unparalleled acoustic performance.

The 100 series system features single or double-leaf doors for seamless passage while maintaining excellent soundproofing capabilities. Its robust outer frame is constructed from 6061 aluminum alloy, complemented by an inner frame consisting of 3.0mm hot-dip galvanized C-shaped steel and 1.2mm hot-dip galvanized square steel tubes, ensuring long-lasting durability. With high-density 100kg/m³ rock wool and a door thickness of 105mm, the 100 series system establishes a new standard in acoustic solutions.

| Product Specifications | |

| Suspension | double suspension |

| Track System | L500 & L600 & L800 & L1000 & G2000 |

| Roller | Dupont POM material & steel roller with safety steel wire |

| Track Load Bearing | L500: 500kg; L600: 600kg L800: 800kg; L1000: 1000kg G2000: 2000kg |

| Panel Thickness | 105mm |

| Panel Configuration | 1.Outer Frame:6061-12um-15hw 2.Inner Frame: 3.0mm hot dip galvanizing C-shape steel+1.2mm hot dip galvanizing square steel tube 3.Rockwool:100kg/m³ 4.Board THK:15mm |

| Vertical Seal | Concave & convex profile with 40N magnetic strip and rubber seal |

| Retractable seal | Top & bottom |

| Mechanism | jack lifting of power 10KN |

| Locking | clockwise rolling |

| Infilled materials | 100kg/m³ rockwool |

| Soundproof treament | steel sheet, sound dampening mat, acoustic panel etc |

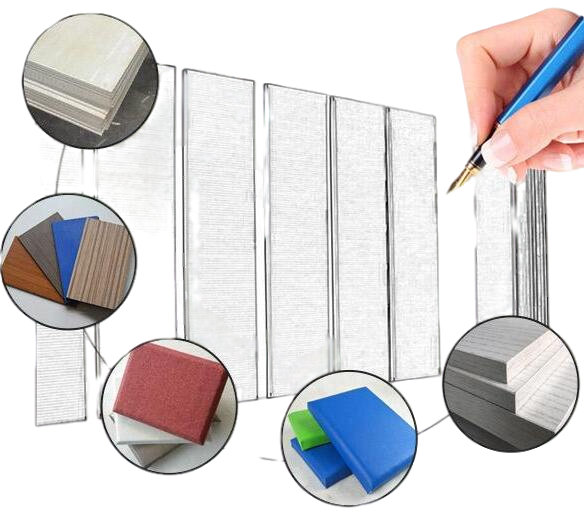

| Base board | 15 mm /18mm plywood /MDF/HDF/HPL |

| Surface finish | Bare board, plywood, melamine, fabric, PU, HPL, wood ect./customized |

| STC | 45db - 56db |

| Weight | 38-60kg/㎡ |

| Fire retartdant | Optional |

| Applicable Height | 5m to 20m |

| Passing door | Single/double leaf |

Top Technical Advantages

TRACK SYSTEM

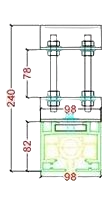

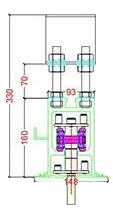

1. The track is made of 6063-T6 aluminium alloy mold the thickness is 8 mm, and the bearcing capacity can reach 1000 kg/m

2. Using steel hanging wheels, the load is 1450kg/piece, the sliding is smooth and does not stop and there is no noise.

3. The hanging wheel is attached with a screw rod to connect the interior of the steel frame structure of the screen the prevent the partition from separting from the hanging wheel

PARTITION SYSTEM

1. Adopt suspension system, according to the principle ofsound bridge, can achieve good sound insulation effect.

2. The door pane! system continuously shakes the top and bottom supports, with a large expansion and contractionrange, and the top support force reaches 180KG.

3. Good adjustment of height error fr situations where the ground plane is not level.

TURNING SYSTEM

1. The track is provided with a guide device and an arc-shaped turing joint, which can realize automatic guide turing

2. High-strength steel, bearing capacity up to 3500kg/m, suitable for paritions above 9 meters

3. According tothe actual situation, the tuming joint of any angle can be customized, and the flexibility is strong.

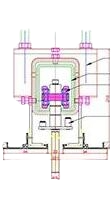

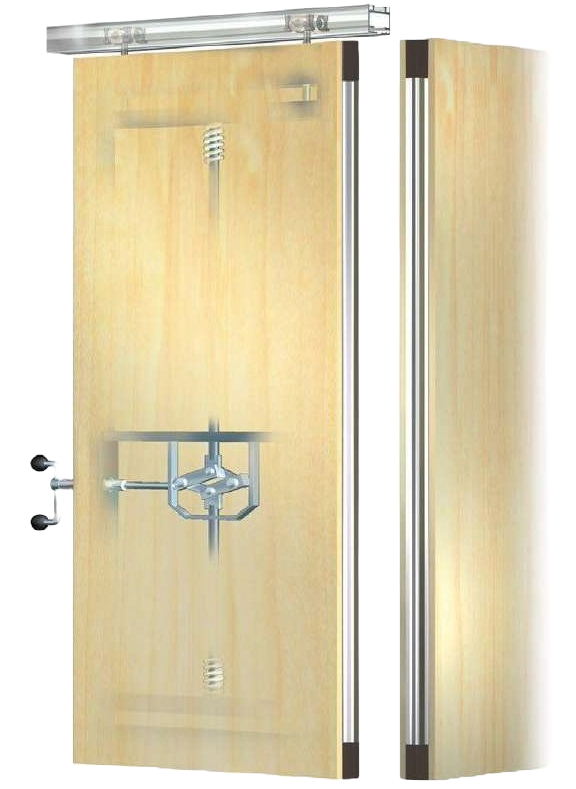

INTERNAL STRUCTURE

1. The interior ofthe partition is welded with square steel to

form a whole frame, and the two sides are edged with aluminum alloy

2. The self:weight is the force of the internal structure, so that the strength and verticality of the screen are better.

3. The service life ofthe partition door panel is greatly improved, and there will be no quality problems such as deformation.

PANEL SPLICING

1. The panel is made of 15mm thick plate, and the jigsaw is made of tongue and groove butt joint.

2. Better sound insulation and smoother surface.

3. Compared with the panel ofthe same industry, ithas great advantages in colision splicing

SOUND INSULATION REINFORCEMENT

1. In addition to gypsum board + steel plate, a special sound insulation mat (SOUNDMAT) is added inside the board

2. Using professional new sound-absorbing, fireproof and environmentally friendly flame retardant resin processing and molding,

3. About 0.8KG per square, light material, with good sound insulation effect.

Adaptable Track System

L600 |

L700 |

L800 |

L1000 |

G2000 |

|

Picture |

|

|

|

|

|

Tech Drawing |

|

|

|

|

|

Track Material |

6061-T6 Aluminium |

6061-T6 Aluminium |

6061-T6 Aluminium |

6061-T6 Aluminium |

Special Steel 2023 with coating |

Wheel Mateerial |

Steel |

Dupont Pom and Steel |

304# Stainless Steel with special bearing |

304# Stainless Steel with special bearing and steel safety wire |

304# Stainless Steel with special bearing and steel safety wire |

Weight |

10.5kg/3m |

26.27kg/3m |

22.23kg/3m |

30.32kg/3m |

42.28kg/3m |

Load Bearing (2 Wheels/Panel) |

600kg /2pcs/panel |

700kg /2pcs/panel |

800kg /2pcs /panel |

1000kg /2pcs /panel |

2000kg /2pcs /panel |

Aplicable Panel |

EG55, EG65, EG85, EG100 |

EG85, EG100 |

EG85, EG100 |

EG85, EG100 |

EG100 |

G2000 |

2M to 6M |

2M to 6M |

4m to 12m |

6m to 15m |

6m to 20m |

The Advantages In Detail

1. Horizontal seals

The principle of double-skin construction is applied consistently in the seal area in order to ensure maximum sound insulation. A spindle mechanism extends the spring-loaded, flexible: double chamber seals against the floor and the ceiling track. Any imegulariies in the flooring are offset by spring-loaded double-cham-ber seals. The contact force of the sealing strips does not place excessive strain on screed floors, but does ensure that the Doormax system is sufficient-ly stable to prevent the panels moving.

2. Corner seals

Doormax resolves the technical issue of comer seals with specially designed elastic comer pieces that also reinforce the stably and sound insulation properties of the system.

3. Vertical seals

All Doormax models have flexible, vertical sealing strips to ensure the best possible seal for maximum sound insulation. The strips extend some distance into the panels to ensure positive interlock.

4. Magnetic strip

The individual panels are centred via the magnetic strips to guarantee sound, positive locking and sealing

5. Cover panels

The cover panels are clipped on as freely oscillating bodies to ensure optimum sound insulation with minimum system weight. The panels can be replaced without removing the elements. Their surfaces can be coated or covered with any conventional interior design material

6. Sound insulation material

The various Egood models can be fited with additional insulation materials according to the. specified acoustic requirements.

7. Operating handle

In manual systems, the element sealing strips are operated using a crank. The crank has a capive bayonet fiting to prevent t from being pulled off. The bayonet arrangement is easy to disengage and prevents crank slippage.

8. Frame

The frame is of torsionally if steel and aluminium construction Transverse forces will not, therefore, cause deformation of the

frame. This, combined with the panels mounted in acoustically free sus- pension, means elements are able to offer both exceptional strength and outstanding sound insulation

9. Roller assemblies

The dampening track roller assemblies prevent the transmission of impact forces and operating noise, so protecting element, track and carrier

Finishes

- Vinyl

- Melamine Covering

- Solid Color

- Wooden Color

- Woven Fabric Covering,

- Foam Padding,

- Acoustic Panels

- Atiicial Leather

- Foam Padding

- High Pressure Laminate

- Plastic Laminate

- Natural Wood Veneer

- Whiteboard,

- Wallpaper

- Customers own materials

Reach Out To Us

Do you want to reach out for more infromation or see how we can help you? Reach out to us by clicking on the button below