100 SERIES AUTOMATIC OPERABLE WALL

Transform Your Space With Doormax

Discover our automatic movable partitions, harnessing state-of-the-art German technology. These partitions, also referred to as movable partition walls, movable panels, or mobile screens, boast ease of installation and reusability, embodying an environmentally conscious and industrially produced solution with fireproof capabilities.

Functionally versatile, these partitions offer a dynamic method for dividing interior spaces, enabling large areas to be effectively segmented into smaller sections. Whether for residential or commercial purposes, these partitions adapt to diverse spatial needs within a structure. Moreover, users have the flexibility to select between electric and manual options, ensuring versatility in both installation and operation.

| Product Specifications | |

| Monolithic width range | 800 - 1500mm / customized |

| Maximum single piece weight | 850Kg / customized |

| Maximum number of running slices | 110 Sheet |

| Operating speed range | 0.10 - 0.20 m/s / customized |

| Input/output voltage | 85-264 volts/24 volts |

| Soundproof treament | steel sheet, sound dampening mat, acoustic panel etc. |

| Base board | 9mm plywood/MDF/ HDF//HPL etc. |

| Surface finish | Bare board, plywood, melamine, fabric, PU, HPL, wood ect./customized |

| STC | 38-56db |

| Fire retartdant | Optional |

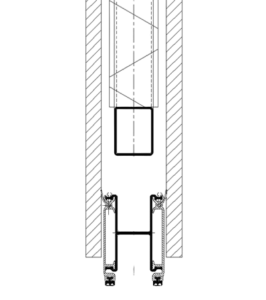

| Applicable Height | 2m to 20m |

| Passing door | Single/double leaf |

| Panel Configuration: Coating THK: um Wesbster Hardness: hw | 1.Frame:6061-12um-15hw 2.Keel:1.0mm hot dip galvanizing steel 3.Rockwool: 55kg/m³ 4.Base Board THK:9mm |

TECNHNICAL ACCESSORIES

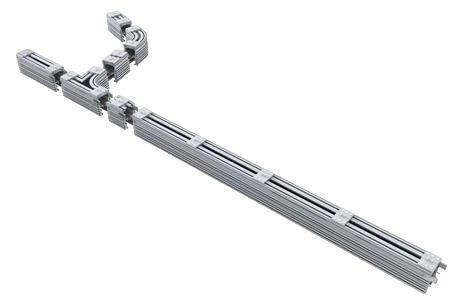

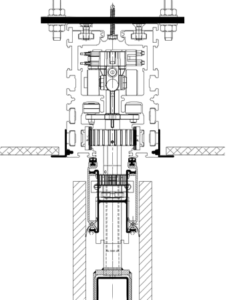

Track System

hard oxidized 6061 aluminum track main weighing wall thickness reaches 12 mm, which provides stable load-bearing support and excellent weather resistance for the entire electric system;

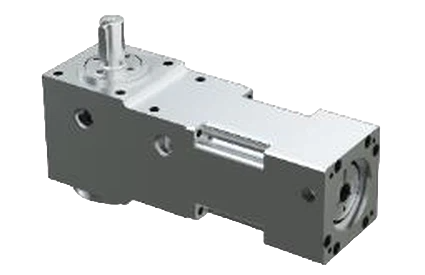

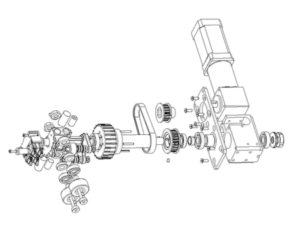

Motion System

The key components of the motion system are all self-developed customized products. The supporting hardware comes from international well-known brand supporting manufacturers, and the quality is stable and reliable;

Motor

Custom 42mm diameter brushless DC motor Voltage

DC 24v

torque -0.185N.m

Rated power -78w

Rated speed -4000rpm Rated current -5.1A Rated

Gearbox

Customized 42mm planetary gear box + umbrella

gear gear boxReduction ratio-1: 74.52

Maximum output torque-15N.m1

Master Controller

Handheld/Wall Color Screen

Control Panel/Tablet PC (optional)

Input voltage-220v (color screen)

control mode-on / off / special

mode screen size-5 inches

Communication mode-radio frequency

Integrated Motor Driver

Brushless DC drive + RF receiving module

Operating speed-can be linearly adjusted 1000-4000rpm

Door opening delay-linearly adjustable 3-999s

Door closing delay-linearly adjustable 3-999s Start

acceleration-10 gears adjustable

PID-encoder parameter setting

Communication mode-radio frequency, mobile phone Bluetooth/wifi (can be customized) spare I/O ports-2

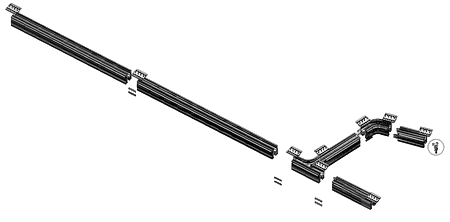

TRACK LAYOUT

The rail system is made of high strength 6061-T5 profile, which provides a good structural foundation for the whole as well as the movement structure. At the same time, the surface of the profile is anodized to improve the anti-corrosion ability of the profile under high salt and high humidity conditions in Shenzhen.

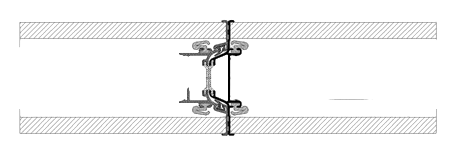

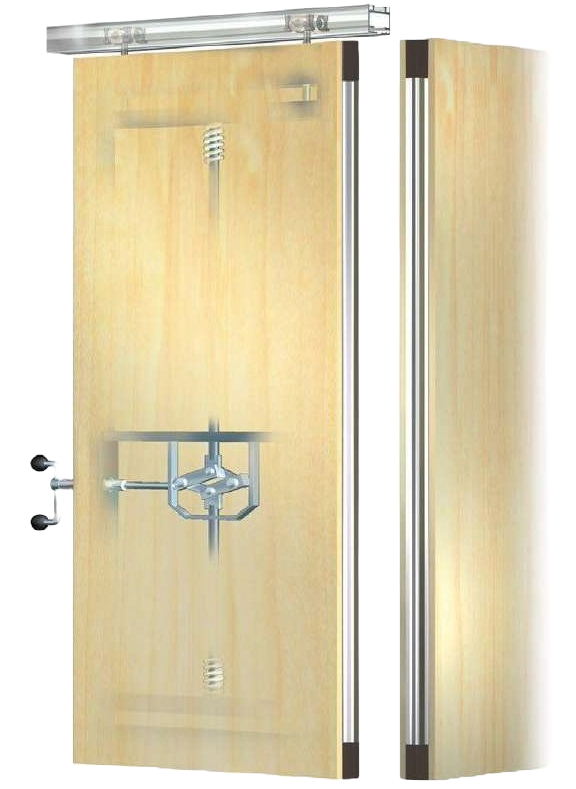

Door panel to touch sealing node

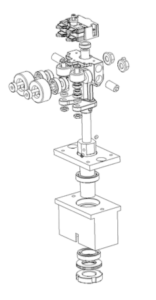

Active Hanging Assembly

Slave Hanger Assembly

Electric Hanging System Nodes

Upper And Lower Sealing Nodes

The Advantages In Details

1. Horizontal seals

The principle of double-skin construction is applied consistently in the seal area in order to ensure maximum sound insulation. A spindle mechanism extends the spring-loaded, flexible: double chamber seals against the floor and the ceiling track. Any imegulariies in the flooring are offset by spring-loaded double-cham-ber seals. The contact force of the sealing strips does not place excessive strain on screed floors, but does ensure that the Doormax system is sufficient-ly stable to prevent the panels moving.

2. Corner seals

Doormax resolves the technical issue of comer seals with specially designed elastic comer pieces that also reinforce the stably and sound insulation properties of the system.

3. Vertical seals

All Doormax models have flexible, vertical sealing strips to ensure the best possible seal for maximum sound insulation. The strips extend some distance into the panels to ensure positive interlock.

4. Magnetic strip

The individual panels are centred via the magnetic strips to guarantee sound, positive locking and sealing

5. Cover panels

The cover panels are clipped on as freely oscillating bodies to ensure optimum sound insulation with minimum system weight.The panels can be replaced without removing the elements. Their surfaces can be coated or covered with any conventional interior design material

6. Sound insulation material

The various Doormax models can be fited with additional insulation materials according to the. specified acoustic requirements.

7. Operating handle

In manual systems, the element sealing strips are operated using a crank. The crank has a capive bayonet fiting to prevent t from being pulled off. The bayonet arrangement is easy to disengage and prevents crank slippage.

8. Frame

The frame is of torsionally if steel and aluminium construction Transverse forces will not, therefore, cause deformation of the

frame. This, combined with the panels mounted in acoustically free sus- pension, means elements are able to offer both exceptional strength and outstanding sound insulation

9. Roller assemblies

The dampening track roller assemblies prevent the transmission of impact forces and operating noise, so protecting element, track and carrier

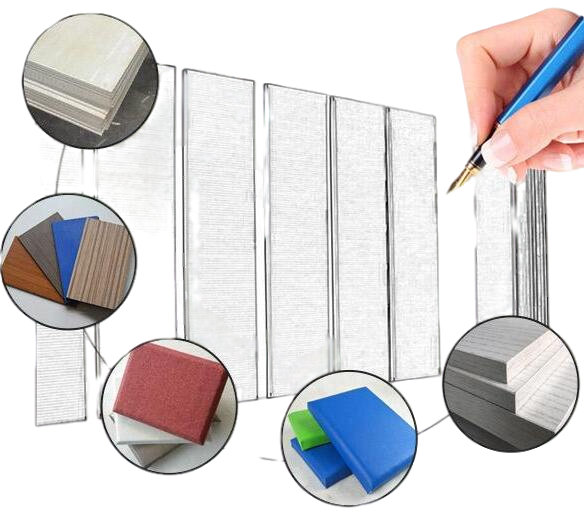

Finishes

- Vinyl

- Melamine Covering

- Solid Color

- Wooden Color

- Woven Fabric Covering,

- Foam Padding,

- Acoustic Panels

- Atiicial Leather

- Foam Padding

- High Pressure Laminate

- Plastic Laminate

- Natural Wood Veneer

- Whiteboard,

- Wallpaper

- Customers own materials

Reach Out To Us

Do you want to reach out for more infromation or see how we can help you? Reach out to us by clicking on the button below